Ts'ebetso ea "Double Mash" e nang le litlamorao tse tharo tse fapaneng tsa khatello ea methapo

Kakaretso

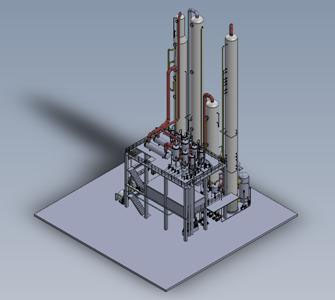

Tlhahiso ea li-column tse peli tsa mokhoa oa ho noa joala ka kakaretso haholo-holo e na le tora e ntle ea II, tora e mahoashe II, tora e hloekisitsoeng ea I, le tora e mahoashe I. Sistimi e le 'ngoe e na le litora tse peli tse mahoashe, litora tse peli tse ntle, le e le' ngoe. tora e kena ka mouoane litora tse 'nè. Khatello e fapaneng pakeng tsa tora le tora le phapang ea mocheso e sebelisoa ho fapanyetsana mocheso butle-butle ka mochine oa ho futhumatsa motlakase ho finyella sepheo sa ho boloka matla. Mosebetsing, litora tse peli tse tala li feptjoa ka nako e le 'ngoe,' me litora tse peli tse ntle ka nako e le 'ngoe li noa joala. Hona joale, mokhoa ona o khothalelitsoe ho bahlahisi ba bangata ba joala le mafura a ethanol.

Ea boraro, litšobotsi tsa tshebetso

1. Tšebeliso e tlaase ea matla, lithane tse 1,2 tsa joala.

2. Mouoane o le mong o feta ka mochine o futhumatsang ho futhumatsa tora e ntle ea II, tora e ntle ea II mouoane o ka holimo oa veine o futhumatsa tora e tala ea II ka reboiler, tora e tala II mouoane oa veine o chesang ka ho toba tora e ntle ea I, le tora e ntle I. tower top wine e feta The reboiler futhumatsang kholomo e tala I. Tora e le 'ngoe e kena ka har'a mouoane le litora tse' nè ho finyella liphello tse tharo tsa mocheso oa ho kopanya ho fihlella ho boloka matla.

3. Ho sebelisa phapang pakeng tsa khatello le mocheso pakeng tsa tora le tora ho fetola mocheso butle-butle ka reboiler, mocheso o ka sebelisoa ho isa tekanyong e kholo, kahoo o boloka matla ka katleho.

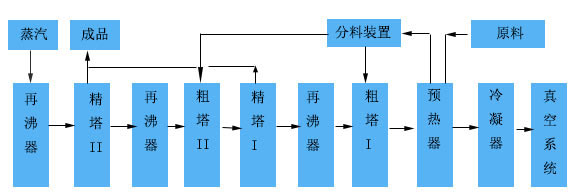

Ea bone, mokhoa

Bohlano, mokhoa oa ho futhumatsa

Senotlolo sa ho boloka matla a ts'ebetso ke mokhoa oa ho futhumatsa. Mouoane o ka sehloohong o futhumatsa ka tsela e sa tobang ke reboiler ho hloekisa tora ea II. Metsi a kolobisitsoeng ka mouoane a futhumatsa setoto se seng se butsoitseng se belisoang le joala bo tala, ebe a khutlela ka tankeng ea metsi a bonolo bakeng sa ho sebelisoa hape; mouoane oa veine o hloekisitsoeng oa tora ea II o feta ka reboiler. Kholomo e tala ea II e futhumetse; mouoane o motle oa I oa veine o futhumatsoa ke reboiler ho ea kholomong e tala ea I.

Ts'ebetsong ena, tora e sa jeleng paate ke tora ea khatello e mpe, tora e mahoashe II le tora e ntle ke litora tsa khatello ea sepakapaka, 'me tora e ntle ea II ke tora ea khatello e ntle. Phapang ea khatello le phapang ea mocheso li sebelisetsoa ho futhumatsa ka mehato. Tora e le 'ngoe e kena ka har'a mouoane le litora tse tharo ho fihlela ho kopana ha mocheso oa likarolo tse tharo ho finyella merero ea ho boloka matla.

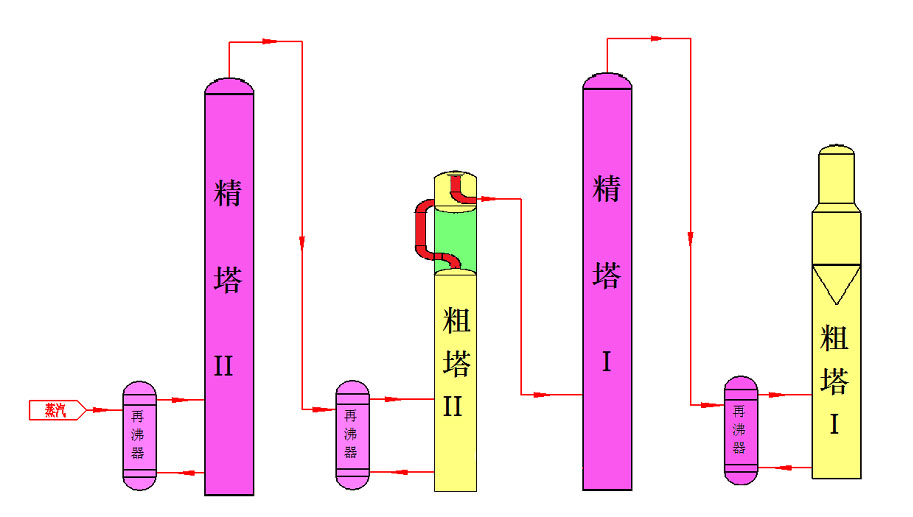

Ea botšelela, mokhoa oa lintho tse bonahalang

Mehato e 'meli ea setoto sa preheated preheated fermentation pele e kena ka holim'a kholomo ea pele ho tlosa aldehyde, ebe e arola setoto ka likarolo tse peli ka morekisi: karolo e' ngoe e kena kholomong e mahoashe II, 'me karolo e' ngoe e kena kholomong e mahoashe I. Ka mor'a hore setoto se lomositsoeng se kene ka har'a tora e tala ea II, mokelikeli o mobe o ntšoa ka tlaase ho tora, 'me joala bo sa hloekang bo kena ka ntle. tora ea I e lokela ho tsepamisa mohopolo le ho lokolloa, 'me karolo ea joala e phethiloeng e ntšoa moleng o ka holimo oa lehlakore.

Ka mor'a botlaaseng ba tora e hloekisitsoeng ke khantša veine le tora e tala I top wine vapor condensate, e kena ka tora e ntle ea II, e tsepamisitse maikutlo le ho tlosa ka tora e ntle ea II, ebe e ntša joala bo bong bo felileng moleng o ka holimo oa lehlakore, le litšila tse phahameng tse belang joalo ka oli ea fusel Ntša karolong e ka tlase ea tora e ntle ea II.

Supa, boemo bo akaretsang ba tšebeliso ea joala le tafole ea papiso ea boleng