Theknoloji ea mouoane le crystallization

Molasses litšila tsa joala sesebelisoa se nang le phello e mehlano ea ho fetoha mouoane

Kakaretso

Mohloli, litšobotsi le kotsi ea metsi a litšila a molasses

Metsi a litšila a joala a Molasses ke metsi a litšila a phahameng haholo le a mebala e phahameng a ntšitsoeng setsing sa tahi sa feme ea tsoekere ho hlahisa joala ka mor'a ho belisoa ha molasses. E ruile ka protheine le lintho tse ling tse phelang, hape e na le matsoai a mangata a sa tloaelehang a kang Ca le Mg le metsoako e phahameng. SO2 joalo-joalo. Ka tloaelo, pH ea metsi a litšila a joala ke 4.0-4.8, COD ke 100,000-130,000 mg/1, BOD ke 57-67,000 mgSs, 10.8-82.4 mg/1. Ho phaella moo, boholo ba mofuta ona oa metsi a litšila ke acidic, 'me' mala o phahame haholo, o sootho-o motšo, haholo-holo o kenyelletsa 'mala oa caramel,' mala oa phenolic, 'mala oa Maillard joalo-joalo. Kaha mokelikeli oa litšila o na le lintho tse tiileng tse ka bang 10%, mahloriso a tlaase 'me a ke ke a sebelisoa. Haeba e ka tšeloa ka kotloloho linōkeng le masimong ntle le ho phekoloa, e tla silafatsa boleng ba metsi le tikoloho ka ho teba, kapa e bake asiti ea mobu le ho kopana, le kholo ea mafu a lijalo. Mokhoa oa ho sebetsana le ho sebelisa mokelikeli oa litšila tsa joala tsa molasses ke bothata bo tebileng ba tikoloho bo tobaneng le indasteri ea tsoekere.

Mokelikeli oa litšila tsa joala oa Molasses o senya haholo 'me o na le chroma e phahameng, eo ho leng thata ho e tlosa ka mokhoa oa biochemical. Ho chesoa ka matla kapa manyolo a metsi a sebetsang hantle haholo ke leano la kalafo le phethahetseng hajoale.

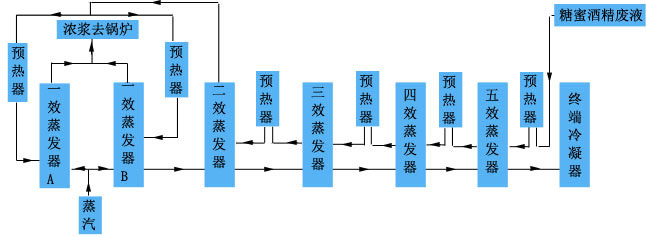

Sesebediswa sena se nka karolo e mehlano e qobellehang ho potoloha mouoane ho tloha tlase, ka mouoane o tletseng joalo ka mohloli oa mocheso, ho futhumatsa ka phello e le 'ngoe le mosebetsi o nang le liphello tse hlano. Mokelikeli oa litšila oa joala oa molasses o nang le motsoako oa 5 ho isa ho 6% o tsitsitse 'me o fetoha mouoane,' me seretse se teteaneng se nang le motsoako oa ≥ 60% se romeloa ho boiler bakeng sa ho chesoa, 'me mocheso o hlahisoang o khotsofatsa haholo mouoane bakeng sa sesebelisoa. Fetola metsi a koaletsoeng ho khutlela karolong e fetileng bakeng sa metsi a hlapollotsoeng.

Ea bobeli, chate ea phallo ea ts'ebetso

Ea boraro, litšobotsi tsa tshebetso

1. Beha evaporator ea spare ho hlakola thepa, e ka hlokomelang ho hloekisa ho sa khaotse le ho netefatsa tlhahiso e tsoelang pele.

2. Sesebelisoa se nka taolo ea lenaneo le ikemetseng ho boloka litšenyehelo tsa basebetsi.

3. Ts'ebetso e phahameng ea ts'ebetso le ts'ebetso e tsitsitseng.

4. Ka ho sebelisa slurry e teteaneng ho khutlela ho boiler, molasses e ka hlahisa joala ntle le ho eketsa mafura.

5. Evaporator ea spare e behiloe bakeng sa phello ea ho ntša, e ka hlokomelang ho hloekisa ho sa khaotse le ho netefatsa tlhahiso e tsoelang pele.

6. Joala bo ka hlahisoa ka molasses ntle le ho kenya mafura ka har'a seretse se teteaneng ho boiler bakeng sa ho sebelisoa hape le molasses.